Precision Molded Aspheric Lenses Products – Injection Molded Plastic Optical Lens – Wavelength

Precision Molded Aspheric Lenses Products – Injection Molded Plastic Optical Lens – Wavelength

Precision Molded Aspheric Lenses Products – Injection Molded Plastic Optical Lens – Wavelength Detail:

Product information:

Optical injection molding techniques is a cost-effective way to produce plastic lens with high precision. It is suitable for making large quantity of plastic lens with spherical, aspheric and free-form surfaces. Injection molding can reproduce optics with a high degree of repeatability and accuracy. Mainly because of the precision built into the molds when they are fabricated and the precision of the mold process.

There are three major impacts of high precision injection molding: the injection molding machine, the molds and the press process. The quality of molds would determine the quality of final part directly. The molds are built to the negative of the part. That is, if you need convex surface, the mold would be concave. The molds are made of alloy, and fabricated with high precision lathe. Multiple parts can be pressed at the same time with multi holes on the mold. They are not necessarily to be the same design; different model of lens can be built in different holes on the same mold and manufactured at the same time to save the molds cost, while reducing the production speed of each model of parts.

Prototyping is necessary before batch production. The molds will be designed and manufactured based on the optical requirements. They might be modified to ensure the final parts can meet the requirement of customer. In batch production, there will be first article inspection as well as in-production inspection during the manufacturing process. And the last part manufactured will be saved for future inspection.

Plastic material cannot stand high temperatures that the coatings applied on the

Specifications

Wavelength infrared provides injection molded plastic lens with 1-12mm in diameter.

|

Material |

Plastic |

|

|

Shape |

Spherical/Aspheric/free-form |

|

|

Diameter |

1-5mm |

5-12mm |

|

Diameter Tolerance |

+/-0.003mm |

|

|

Sag Tolerance |

+/-0.002mm |

|

|

Surface Accuracy |

Rt<0.0006mm △Rt<0.0003mm |

Rt<0.0015mm △Rt<0.0005mm |

|

ETV |

<0.003mm |

<0.005mm |

|

Clear Aperture |

>90% |

|

|

Coating |

Dielectric/Metallic film |

|

Remarks:

Customization available for this product to suit your technical requirements. Let us know your required specifications.

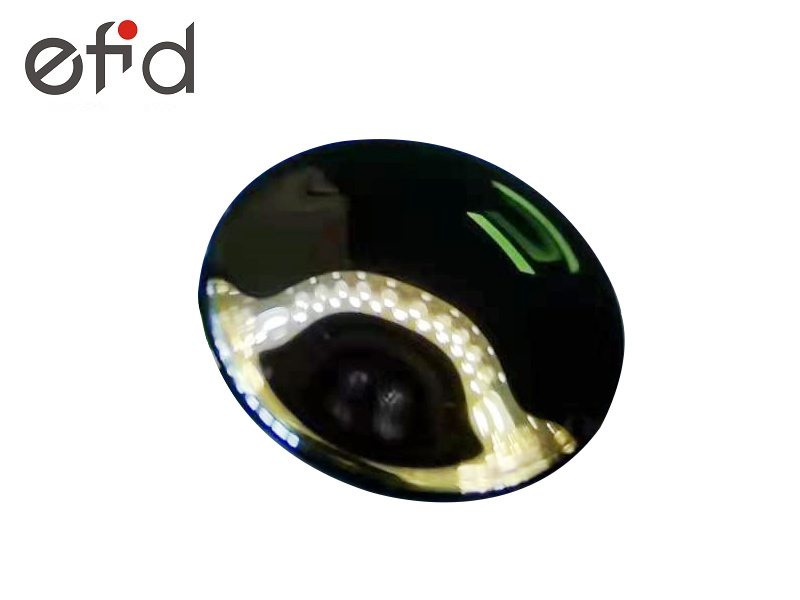

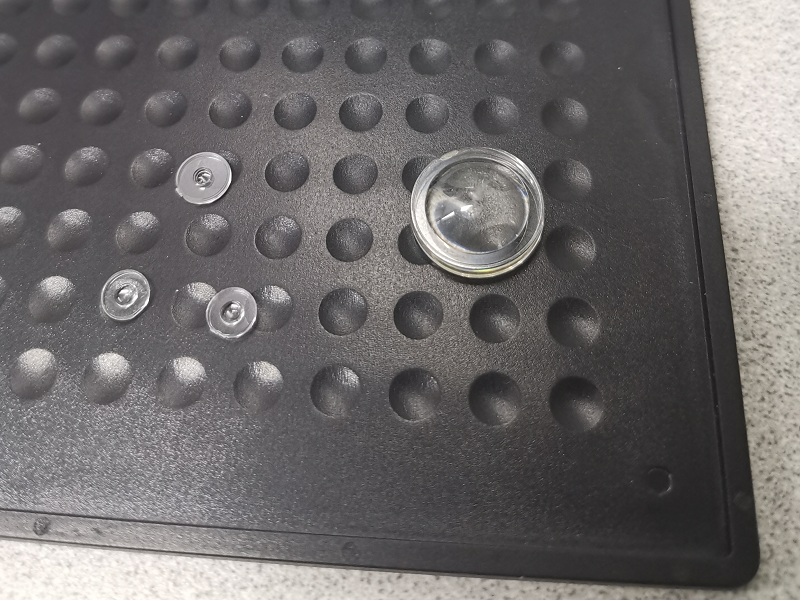

Product detail pictures:

Related Product Guide:

Our staff are usually in the spirit of "continuous improvement and excellence", and while using the top-quality high-quality items, favorable value and superior after-sales services, we try to acquire each and every customer's belief for Precision Molded Aspheric Lenses Products – Injection Molded Plastic Optical Lens – Wavelength , The product will supply to all over the world, such as: Guyana, Malta, Malaysia, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

PRODUCT CATEGORIES

Wavelength has been focused on providing high precision optical products for 20 years